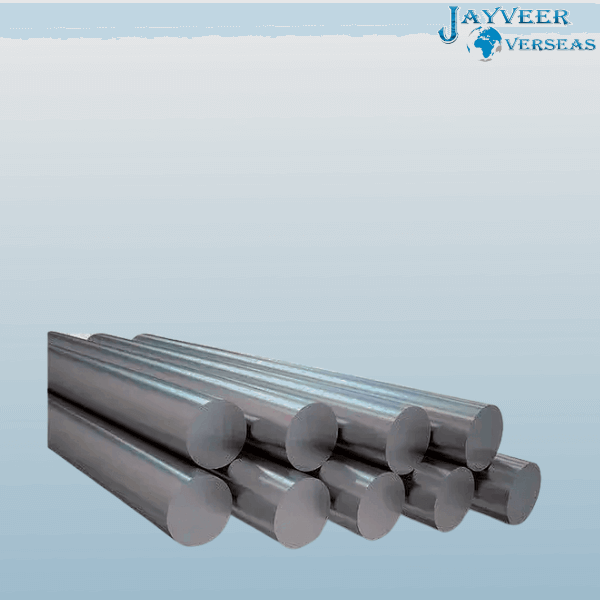

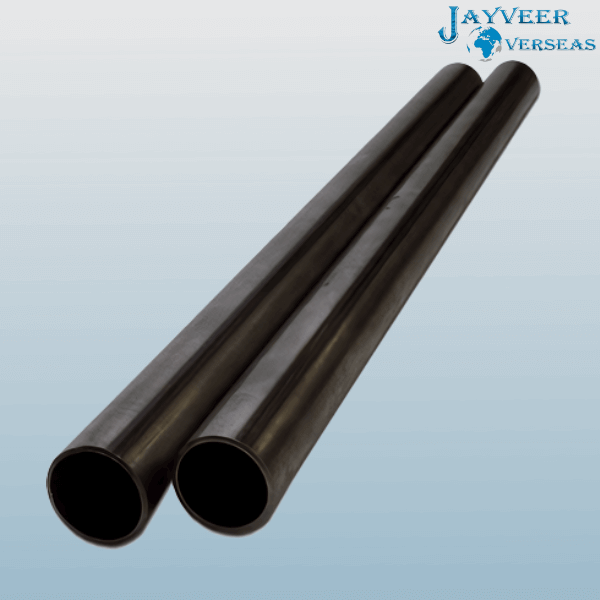

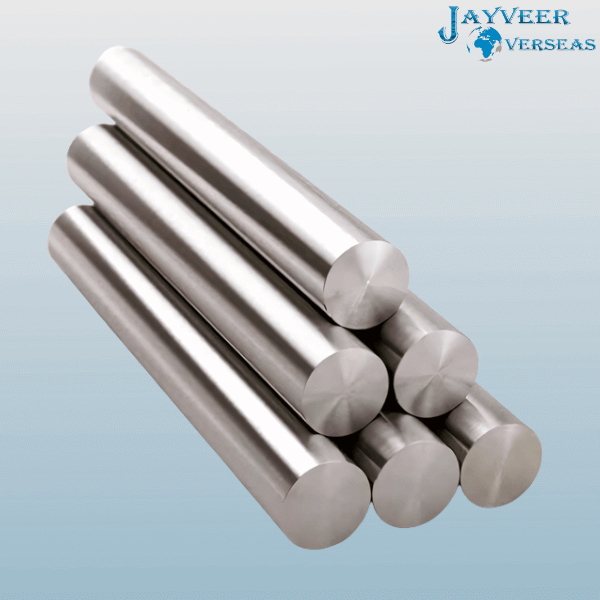

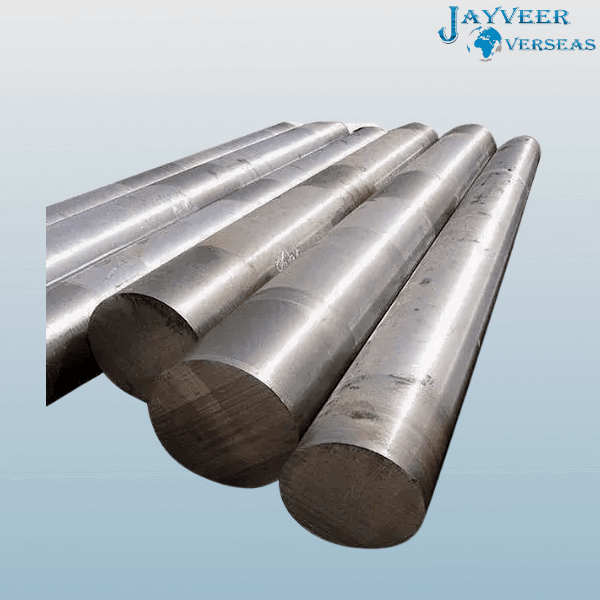

Black Bar

Black bars are a type of steel that has been treated with a black oxide finish to give them their distinctive dark color. This finish is applied through a chemical process that creates a protective layer on the steel’s surface, which helps prevent rust and corrosion.

Black bars are often used in construction and manufacturing applications due to their strength and durability. They are able to withstand high levels of stress and tension, making them suitable for use as structural elements in buildings and other structures. They are also resistant to rust and corrosion, making them a good choice for outdoor use.

In addition to their strength and durability, Black bars are also highly versatile. They can be cut and shaped into a variety of different forms, making them suitable for use in a range of applications. They can also be polished or brushed to create different finishes, allowing them to be incorporated into a variety of design styles.

Hastelloy C22 Black Rod, ASME SA276 SS 310 Black Bar, UNS N08904 Black Rod, ASME SA479 SS 316 Black Bar, 310 Stainless Steel Black Rod, DIN 1.4301 Black Rod, UNS S30400 Black Bar, ASTM A276 Type SS 304 Black Bar.

One of the key properties of the Black bar is its ability to resist stains and fingerprints. This makes them a popular choice for use in kitchen and bathroom applications, where they can maintain their clean and sleek appearance even with frequent use.

Overall, Black bars are a strong and durable material suitable for use in various applications. Their corrosion-resistant properties, versatility, and resistance to stains make them a popular choice for designers and architects looking for a high-quality, functional material.

The size and dimensions of black bars can vary depending on the specific application and the user’s needs. They can be produced in a range of sizes, from small bars that are only a few inches in length to large bars that are several feet long. The thickness and width of the bars can also vary, with some being thin and narrow while others are thick and wide.

Our company takes great care in packaging our black bars to ensure they arrive in perfect condition at their destination. We use high-quality materials such as bubble wrap and sturdy boxes to protect the bars during transportation. We also carefully label and organize the packages to ensure they are easy to handle and unload at the final destination. We pride ourselves on our attention to detail and commitment to customer satisfaction, and we strive to ensure that our black bars are packed with the utmost care and professionalism.

UNS N08020 Black Rod Supplier, Hastelloy C276 Black Bar Exporter, UNS S31600 Black Rod Exporter, WRN 1.4401 Black Bar Manufacturer, Duplex 2205 Black Rod Stockist, UNS S31000 Black Bar Supplier, 304 Stainless Steel Black Bar Stockist.

Specification:- Black Bar

| Standard: | ASTM, ASME, DIN, BS, EN, IS, AMS, JIS, IBR & Other International Standards. |

| Materials: | Stainless Steel Black Bar,Carbon Steel Black Bar,Alloy Steel Black Bar,Copper Nickel Black Bar,Hastelloy Black Bar,Duplex / Super Duplex Steel Black Bar, Incoloy / Inconel Black Bar, Monel Black Bar, Nickel Black Bar, Titanium Black Bar, 253MA Black Bar, AL6XN Black Bars, Custom 450 Black Bar, Jethete Black Bars, Beryllium Copper Black Bar, |

| Tolerance: | Black Bar (As per IS-3739 grd II std) Bright Bar ( As per ISO H8, H9, H10, H11 also as per ASTM A484, DIN 17440, 671 or as per mutual agreement.) |

| Length: | Black Bar (3 to 6 meters +0.1 mtr) |

| Straightness: | Black Bar (5mm / mtr.) |

| Mechanical Properties: | Black Bar (Mechanical Properties) |

| Delivery Condition: | Black Bar ( Hot Rolled – Straightened, Hot Rolled – Annealed – Straightened, Hot Rolled – Soln. Ann. – Straightened) |

| Order Services | Machining (CNC), Centreless Grinding (CG), Heat Treatment, Anneling, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication, |

| Test Certificate | Manufacturer Test Certificate / Laboratory Test Certificate from Govt. Approved Lab / Under tdird Party Inspection & witd Excise Gate Pass to avail Modvat benefit. |

| Bar Finishing | Bright, Polish & Black |

Dimensions :- Black Bar

| Diameter or Width (mm) | Weight per meter | Sectional Area | Perimeter | |||

| Square (kg) | Round (kg) | Square (cm²) | Round (cm²) | Square (cm) | Round (cm) | |

| 5.0 | 0.20 | 0.15 | 0.25 | 0.20 | 2.0 | 1.57 |

| 5.5 | 0.24 | 0.19 | 0.30 | 0.24 | 2.2 | 1.78 |

| 6.0 | 0.28 | 0.22 | 0.36 | 0.28 | 2.4 | 1.88 |

| 7.0 | 0.38 | 0.30 | 0.49 | 0.38 | 2.8 | 2.20 |

| 8.0 | 0.50 | 0.39 | 0.64 | 0.50 | 3.2 | 2.51 |

| 9.0 | 0.64 | 0.50 | 0.81 | 0.64 | 3.6 | 2.83 |

| 10 | 0.73 | 0.63 | 1.00 | 0.79 | 4.0 | 3.14 |

| 11 | 0.95 | 0.75 | 1.21 | 0.95 | 4.4 | 3.46 |

| 12 | 1.13 | 0.89 | 1.44 | 1.13 | 4.8 | 3.77 |

| 14 | 1.54 | 1.21 | 1.96 | 1.54 | 5.6 | 4.40 |

| 16 | 2.01 | 1.58 | 2.56 | 2.01 | 6.4 | 5.03 |

| 18 | 2.54 | 2.00 | 3.24 | 2.54 | 7.2 | 5.65 |

| 20 | 3.14 | 2.47 | 4.00 | 3.14 | 8.0 | 6.28 |

| 22 | 3.80 | 2.98 | 4.84 | 3.80 | 8.8 | 6.91 |

| 25 | 4.91 | 3.85 | 6.25 | 4.91 | 10.0 | 7.85 |

| 28 | 6.15 | 4.83 | 7.84 | 6.16 | 11.2 | 8.80 |

| 32 | 8.04 | 6.31 | 10.24 | 8.04 | 12.8 | 10.05 |

| 36 | 10.17 | 7.99 | 12.96 | 10.18 | 14.4 | 11.31 |

| 40 | 12.56 | 9.86 | 16.00 | 12.57 | 16.0 | 12.57 |

| 45 | 15.90 | 12.49 | 20.25 | 15.90 | 18.0 | 14.14 |

| 50 | 19.62 | 15.41 | 25.00 | 19.64 | 20.0 | 15.71 |

| 56 | 24.62 | 19.34 | 31.36 | 24.63 | 22.4 | 17.59 |

| 63 | 31.16 | 24.47 | 36.69 | 31.17 | 25.2 | 19.79 |

| 71 | 39.57 | 31.08 | 50.41 | 39.59 | 28.4 | 22.31 |

| 80 | 50.24 | 39.46 | 64.00 | 50.27 | 32.0 | 25.13 |

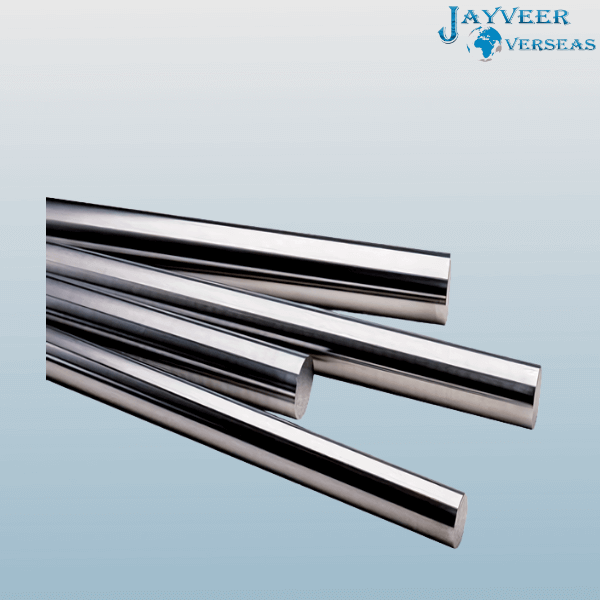

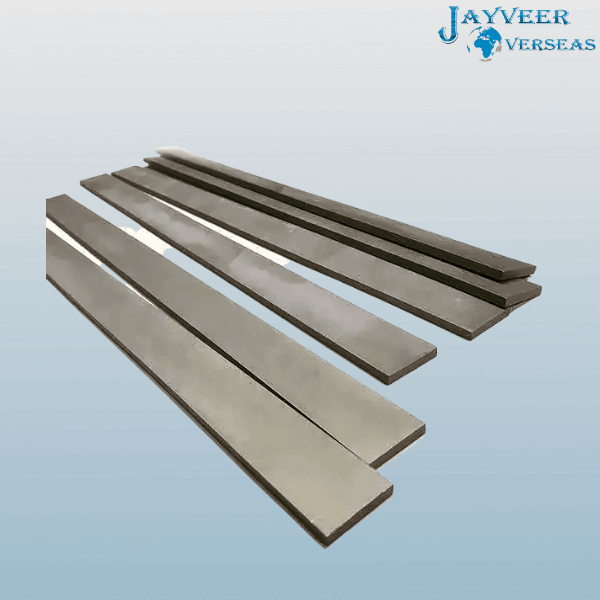

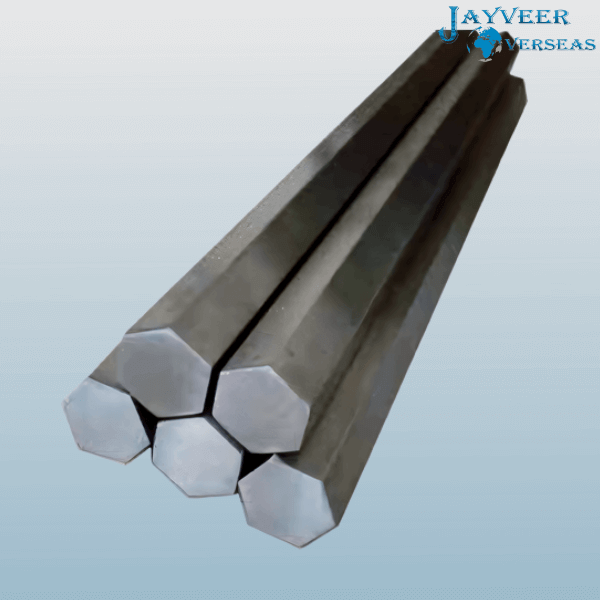

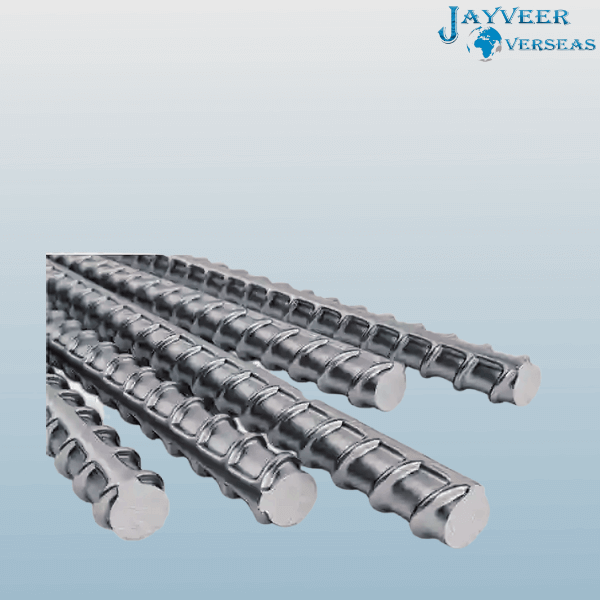

Other Types :- Black Bar

Price List :- Black Bar

| Round Bars | US $1000-2500 / Ton |

| Square Bars | US $1000-2500 / Ton |

| Flat Bars | US $1.5-4.5 / Kilogram |

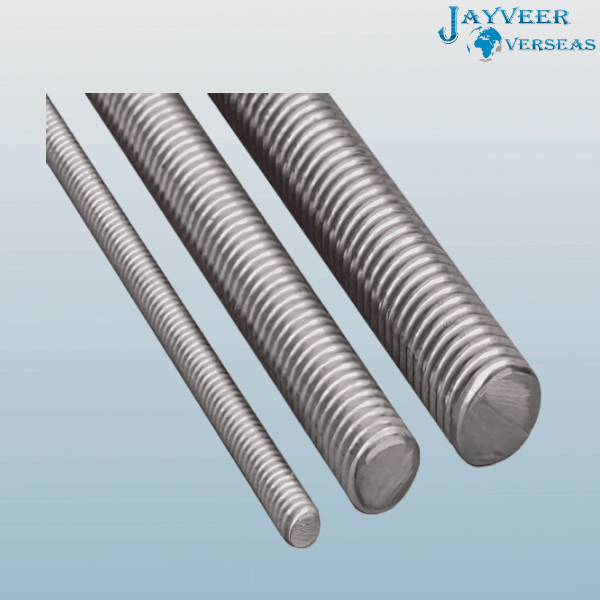

| Threaded Bars | US $1800-2300 / Ton |

| Hollow Bars | US $1550-2400 / Ton |

| Hexagonal Bars | US $1800-2300 / Ton |

| Triangular Bars | US $1300-2600 / Metric Ton |

industries we serve :

- Biodiesel and ethanol plants and tanks

- Palm oil and wine storage tanks

- Bridges, flood gates, and sluice gates

- Washers and paper machine parts

- Pulp and paper mill equipment

- Mixers and agitators

- Architectural applications

- Waste water handling systems

- Ethanol production components

- Desalination system chambers and evaporators

- External absorber and outlet duct reinforcements

- Chemical process pressure vessels, piping and heat exchangers

- Pressure vessels, heat exchangers, tanks, piping systems and tankers

- Hydrogen peroxide bleaching reactors, digesters, and white liquor storage tanks

Packaging Used by us :

We ship our stainless steel metal products in industry leading packaging designed to ensure your order reaches its destination safely. We offer multiple packaging options to meet your specific requirements. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging. We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

- Shrink-wrapped

- Carton boxes

- Wooden pallets

- Wooden boxes

- Wooden crates

Quality and tests Done by us :

- Positive material recognition

- Mechanical examining like tensile, Elongation and reduction of area.

- Large-scale test

- Chemical examination-Spectro analysis

- Firmness test

- Pitting protection test

- Hydrogen-effected cracking test approved by NACE TM0284

- Small tests

- X-ray test

- Impact analysis

- Eddy current examining

- Hydrostatic analysis

- Prompt test

- Sulfide stress corrosion test approved by NACE TM 0177

- Curve test

-

Related Search Queries

-

City We Supply

-

Country We Export